In today’s fast-paced manufacturing landscape, ensuring precision and quality is non-negotiable. Industries are increasingly turning to Video Measuring Machines to meet stringent requirements for accuracy and efficiency. These systems have revolutionized quality control, replacing traditional tools with advanced, non-contact measurement solutions. In this comprehensive guide, we delve into what makes a Video Measuring Machine indispensable for modern production and why manufacturers around the world, including those partnering with Hansvue, are investing in these powerful devices.

Understanding Video Measuring Machines

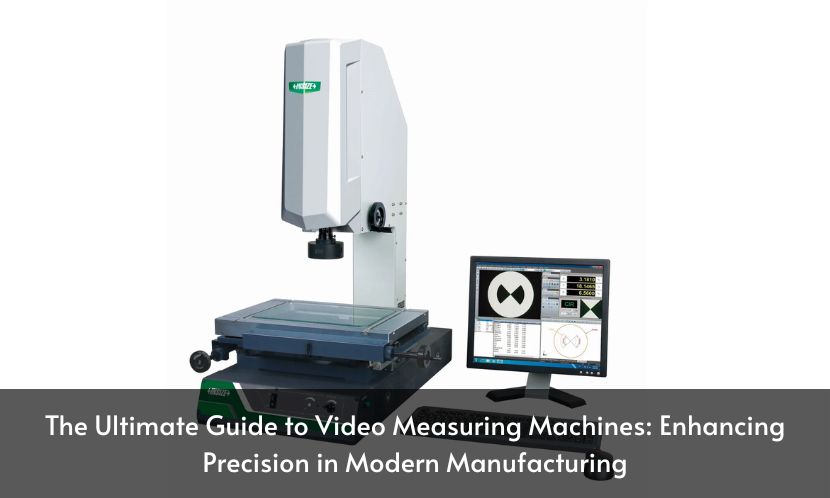

A Video Measuring Machine (VMM), also known as a vision measuring system, is a non-contact device that uses optical systems, high-resolution cameras, and software algorithms to inspect and measure small components with remarkable precision. Unlike contact-based systems, VMMs use light and video imaging to analyze the geometric properties of objects, making them ideal for delicate or intricate parts.

By using computer-controlled stages, lighting, and optics, a Video Measuring Machine captures detailed dimensional data, which is critical in industries such as electronics, aerospace, and medical device manufacturing. Companies like Hansvue provide a wide range of video measuring systems with capabilities tailored to various industrial needs.

Key Features of Video Measuring Machines

When evaluating a Video Measuring Machine, it’s essential to understand the features that contribute to its effectiveness:

High-Resolution Imaging: VMMs are equipped with advanced CCD or CMOS cameras that can capture minute details of a component.

Precision Optics and Lenses: Zoom and telecentric lenses ensure minimal distortion, enhancing measurement accuracy.

Multi-Axis Measurement: Systems often include X, Y, and Z axis movement, allowing 3D analysis of objects.

Advanced Software Integration: Software allows users to automate measurements, generate reports, and perform complex analysis.

Illumination Systems: LED ring lights, backlights, and coaxial lights provide versatile lighting conditions to suit different materials and surfaces.

Applications of Video Measuring Machines in Industry

The Video Measuring Machine has found widespread application across various industries due to its versatility and accuracy. Here are some common uses:

1. Electronics Manufacturing

Circuit boards, microchips, and connectors require micron-level accuracy. VMMs can inspect these components without risk of damage.

2. Automotive and Aerospace

Complex geometries in automotive parts and aerospace components benefit from the multi-axis, high-resolution capabilities of video measurement.

3. Medical Device Manufacturing

Surgical tools, implants, and precision instruments demand consistent quality, which a Video Measuring Machine can provide through non-invasive testing.

4. Plastic and Molded Part Inspection

Injection-molded parts often have intricate details. VMMs ensure all specifications are met before parts go into assembly.

Companies using Hansvue’s systems benefit from the flexibility to measure a wide range of component types without sacrificing accuracy or speed.

Advantages Over Traditional Measuring Tools

Traditional measuring tools like calipers, micrometers, and coordinate measuring machines (CMMs) are still widely used, but Video Measuring Machines offer distinct advantages:

Non-Contact Measurement: Reduces wear and eliminates the possibility of deforming soft or delicate parts.

Speed and Automation: Automated programs allow batch measurements, reducing inspection time dramatically.

Superior Accuracy: Optical magnification and digital imaging capture minute features with exceptional precision.

Versatile Measurements: Handle complex geometries that are difficult or impossible for mechanical tools to measure.

Data and Reporting: Digital integration makes it easier to store, analyze, and report data for compliance and quality assurance.

Choosing a Video Measuring Machine from Hansvue ensures users gain all these advantages along with industry-specific customization.

Future Trends in Video Measuring Technology

The Video Measuring Machine landscape is evolving rapidly, with innovations aimed at improving precision, efficiency, and integration:

AI and Machine Learning: These technologies will enhance feature recognition, reduce measurement time, and improve automation.

IoT Integration: Real-time monitoring and remote diagnostics through cloud-based systems.

Multi-Sensor Systems: Combining video with tactile and laser sensors to deliver hybrid measurements.

Miniaturization: More compact systems for smaller workspaces without sacrificing functionality.

Greater Automation: Integration with production lines for continuous, in-process inspection.

Hansvue continues to innovate with next-generation video measuring systems that integrate many of these advanced technologies, providing future-proof solutions for manufacturers.

Hansvue's Video Measuring Machines: A Closer Look

Hansvue is a leading provider of Video Measuring Machines designed to meet the highest standards of industrial precision. Their product lineup includes:

Manual Video Measuring Systems: Ideal for small workshops needing high-precision but cost-effective solutions.

CNC Video Measuring Systems: Automated, high-speed machines designed for batch inspections and large-scale production environments.

Hybrid Vision Systems: Combine video, laser, and contact probes for comprehensive dimensional analysis.

Key benefits of choosing Hansvue include:

Exceptional Accuracy: Sub-micron precision ensures quality control at the highest level.

User-Friendly Interfaces: Intuitive software that minimizes the learning curve.

Customization Options: Systems tailored to specific industries, including medical, automotive, and electronics.

Responsive Support: Hansvue provides training, support, and calibration services to maximize system uptime and productivity.

Whether you’re looking for an entry-level unit or a high-end automated system, Hansvue has a Video Measuring Machine to match your quality assurance goals.

Conclusion

As industries move toward zero-defect manufacturing and higher product complexity, the role of the Video Measuring Machine becomes increasingly vital. These systems provide unmatched precision, efficiency, and adaptability across a wide range of applications. With advancements in imaging technology, automation, and software, VMMs are set to remain a cornerstone of modern quality control processes.

Hansvue’s lineup of video measuring systems offers scalable, reliable, and future-ready solutions for businesses that demand excellence. If you’re looking to upgrade your inspection process, now is the time to explore the benefits of integrating a Video Measuring Machine from Hansvue into your operations.