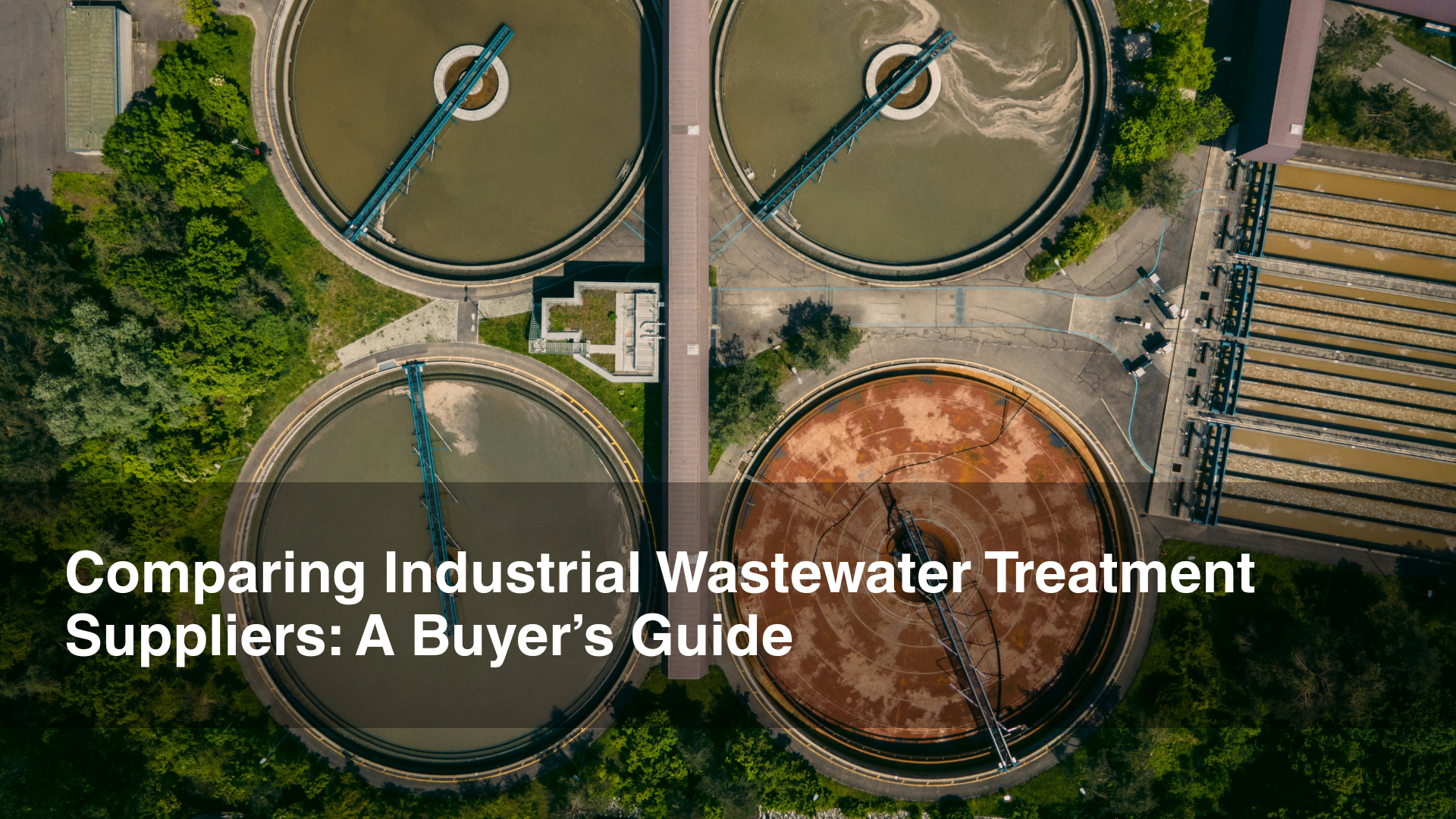

Understanding Industrial Wastewater Treatment

Industrial wastewater treatment is a crucial process aimed at removing contaminants and harmful substances generated by various industries before the water is released back into the environment. This procedure plays a pivotal role in minimizing the impact of industrial activities on ecosystems and public health. There are numerous industries, such as pharmaceuticals, food processing, textiles, and chemicals, that produce wastewater laden with pollutants that can significantly harm aquatic life and water resources if not treated properly.

The wastewater treatment process typically involves multiple stages, each designed to target specific types of contaminants. Initially, physical methods such as screening and sedimentation are utilized to remove larger solid particles. Following this, biological treatment methods, which involve microorganisms, are employed to break down organic matter and reduce biochemical oxygen demand (BOD). Finally, chemical treatments may be necessary to eliminate hazardous chemicals, pathogens, and residual contaminants, ensuring that the treated effluent meets regulatory standards for discharge.

Moreover, industrial wastewater treatment is not solely about compliance with environmental regulations; it also reflects a commitment to corporate social responsibility. Industries that prioritize effective treatment demonstrate their commitment to sustainability and the preservation of natural resources. This is becoming increasingly significant in today’s market, as consumers and stakeholders are more aware of environmental issues and hold companies accountable for their ecological footprint.

Proper treatment of industrial wastewater safeguards public health by reducing the risk of waterborne diseases and preserving clean water supplies. By partnering with the right industrial wastewater treatment supplier, organizations can ensure that they implement the most effective processes tailored to their specific needs, thus enhancing operational efficiency while protecting the environment.

The Role of Industrial Wastewater Treatment Suppliers

Industrial wastewater treatment suppliers play a vital role in managing the complexities of wastewater generated from industrial processes. These suppliers are responsible for providing the necessary technology, equipment, and expertise to ensure that wastewater is treated effectively before it is discharged into the environment. One of their primary functions is to supply advanced treatment systems that can efficiently reduce contaminants to meet regulatory standards. This entails not only the delivery of equipment such as clarifiers, filters, and bioreactors but also the integration of innovative technologies tailored to specific industry requirements.

Furthermore, these suppliers must offer comprehensive support and services beyond just equipment provision. It is imperative that they possess a skilled team of experts who can help businesses identify their wastewater treatment needs through thorough assessments. This is particularly crucial, as understanding the unique challenges presented by different types of industrial wastewater is essential for selecting the appropriate treatment methods. An established supplier will have the expertise to navigate these complexities, thereby ensuring compliance with environmental regulations and contributing to sustainable industrial practices.

In addition to equipment and technical support, effective industrial wastewater treatment suppliers focus on developing customized solutions. This involves collaborating with clients to design systems that are not only efficient but also cost-effective. By providing training, troubleshooting support, and regular maintenance services, suppliers can help industries optimize their wastewater treatment processes, minimize operational costs, and enhance overall environmental stewardship. Hence, when selecting a supplier, it is crucial to evaluate their experience, the range of solutions offered, and their ongoing commitment to customer service and technical support to ensure an effective partnership.

Operational Cost Reduction Through the Right Supplier

Partnering with the right industrial wastewater treatment supplier can result in significant operational cost reductions for businesses. A competent supplier not only provides advanced technology but also implements practices that can lead to minimized expenses in various areas such as energy consumption, chemical usage, and maintenance schedules.

One of the critical aspects of operational cost reduction is energy efficiency. A proficient wastewater treatment supplier often utilizes state-of-the-art systems designed to consume less energy. For example, suppliers might offer equipment that employs advanced aeration techniques or innovative membrane filtration systems, which operate efficiently and help lower electricity bills. In a case study involving a manufacturing plant, the introduction of energy-efficient treatment systems allowed the facility to reduce its energy consumption by up to 30%, leading to considerable savings over time.

Chemical usage is another area where a capable supplier can help cut down costs. By leveraging superior treatment processes and technologies, suppliers can reduce the quantity of chemicals needed for effective wastewater treatment. For instance, using biologically based treatment methods can decrease the reliance on harsh chemicals, thus lowering both procurement costs and the potential for hazardous waste management issues. A chemical analysis conducted in partnership with a chosen supplier highlighted a 25% reduction in chemical usage, further emphasizing the financial benefits of effective supplier partnerships.

Optimizing maintenance schedules is an often-overlooked factor that contributes to operational cost efficiency. A reliable wastewater treatment supplier can provide data-driven insights for preventive maintenance, allowing facilities to avoid unexpected downtimes and costly repairs. By establishing a proactive maintenance plan tailored to the specific systems in use, businesses can extend the lifespan of their equipment while simultaneously reducing operational hiccups.

Ultimately, the importance of selecting the right wastewater treatment supplier cannot be overstated. From conserving energy to minimizing chemical usage and optimizing maintenance, a skilled supplier can collectively drive down operational costs and enhance overall efficiency within industrial settings.

Enhancing Sustainability Efforts Through a Strategic Supplier

In today’s environmental landscape, the importance of sustainable practices cannot be overstated, particularly for industries that generate substantial wastewater. Partnering with the right industrial wastewater treatment supplier is pivotal for enhancing sustainability efforts within a company. By selecting a supplier that prioritizes innovative, environmentally-friendly technologies, organizations can significantly reduce their ecological footprint. These technologies may include advanced filtration systems, biological treatments, and chemical processes engineered to minimize harmful discharges into local water bodies.

Moreover, effective wastewater management involves not only treatment but also the recycling and reusing of water. A reputable supplier will employ strategies that allow firms to reclaim a portion of the wastewater generated, treating it for reuse in various applications such as irrigation, cooling processes, or even for use within the production line. This approach not only conserves water but also reduces the demand for fresh water sources, contributing to a more sustainable operation.

Additionally, aligning wastewater management practices with corporate social responsibility (CSR) goals can enhance a company’s reputation and stakeholder trust. By demonstrating a commitment to environmental stewardship through responsible wastewater treatment, companies can improve their industry standing and appeal to environmentally-conscious consumers. Engaging with a supplier that embodies these values creates a mutually beneficial relationship; suppliers provide the necessary technology and expertise while companies reinforce their commitment to sustainability.

In summary, fostering a strategic partnership with a reliable industrial wastewater treatment supplier is essential for companies looking to elevate their sustainability initiatives. By investing in eco-friendly technologies and adopting practices for recycling and reusing wastewater, organizations not only comply with regulatory standards but also take significant strides toward environmental stewardship. These efforts ultimately align with broader CSR objectives and enhance their overall sustainability footprint.

Ensuring Compliance with Regulations

Compliance with environmental regulations is paramount for industries that generate wastewater. Regulatory agencies implement a myriad of standards that dictate how wastewater must be treated before it is discharged into natural water bodies. These regulations, which vary by region and industry, aim to protect public health and preserve the environment, necessitating that companies adhere to strict operational guidelines. For instance, the Clean Water Act in the United States establishes benchmarks for effluent discharges and encourages industries to adopt best management practices.

Engaging with a reliable industrial wastewater treatment supplier can significantly streamline the process of regulatory compliance. A well-informed supplier possesses an in-depth understanding of the current regulations pertaining to wastewater treatment, including any updates or changes in legal requirements. They can assist companies in developing customized solutions that meet regulatory standards, thereby minimizing the risk of non-compliance. Employing advanced treatment technologies, a reputable supplier ensures that the wastewater treatment processes not only conform to regulations but are also sustainable and efficient.

Moreover, prevention of potential fines and legal repercussions stems from proactive compliance. Companies that fail to meet wastewater regulations may face hefty penalties, including fines, operational shutdowns, or even legal actions, causing significant financial and reputational damage. By partnering with an established supplier, businesses gain access to a wealth of resources, including training and support, to better understand and implement the necessary procedures and technologies. This partnership not only bolsters the company’s compliance efforts but also contributes to its corporate social responsibility objectives and enhances its reputation within the industry.

Ultimately, ensuring compliance with eminent regulations is a critical factor in the sustainable management of industrial wastewater. A robust partnership with the right supplier not only delivers innovative solutions but also safeguards businesses against potential legal challenges associated with wastewater discharge.

Evaluating Industrial Wastewater Treatment Supplier Capabilities and Expertise

When selecting an industrial wastewater treatment supplier, it is crucial to assess their capabilities and expertise comprehensively. This evaluation process should focus on several key factors, including experience, certifications, technological capabilities, and customer feedback. Each of these elements plays a significant role in determining the supplier’s ability to meet your specific treatment needs effectively.

Experience is a vital consideration; suppliers with extensive industry knowledge have often encountered various wastewater challenges and have developed effective solutions. Their understanding of different treatment methods and regulatory requirements can significantly influence the success of your wastewater management strategy. Furthermore, a supplier’s history of successful project completions can provide insight into their reliability and performance.

Certifications also merit careful examination. Reputable suppliers typically hold industry-standard certifications, which demonstrate their adherence to best practices and compliance with regulatory requirements. Certifications such as ISO 9001 or specific environmental standards can serve as indicators of a supplier’s commitment to quality and sustainability. It is beneficial to inquire about their certifications during the assessment process.

Technological capabilities form another critical component of evaluation. Suppliers with advanced treatment technologies can offer more effective and efficient solutions. Understanding the range of technologies employed—such as membrane filtration, biological treatment systems, or chemical treatment methods—can aid in identifying a supplier that aligns with your operational requirements. Additionally, inquire whether the supplier is open to innovation and regularly updates their systems to incorporate the latest advancements in wastewater treatment.

Lastly, customer feedback is an invaluable resource when assessing potential suppliers. Reviews, case studies, and references can provide insight into previous clients’ satisfaction and the supplier’s overall performance. Engaging with other businesses in your industry may yield recommendations and cautionary tales that guide your decision-making process. By critically analyzing these factors, you will be better equipped to identify the right industrial wastewater treatment supplier who can meet your operational and environmental goals.

Case Studies of Successful Supplier Partnerships

Partnering with an adept industrial wastewater treatment supplier can significantly enhance both operational efficiency and environmental compliance. Numerous case studies have illustrated the tangible benefits of such alliances across various industries. One notable example involves a textile manufacturing company that faced challenges in managing its effluent. By collaborating with a specialized wastewater treatment supplier, the company implemented a state-of-the-art treatment system tailored to its specific waste profile. This partnership not only facilitated compliance with local environmental regulations but also led to a 30% reduction in overall wastewater treatment costs. The supplier’s expertise allowed for the recovery of valuable resources, such as water and chemicals, contributing to increased sustainability within the manufacturing process.

Another compelling case study emerges from the food processing sector, where an organization was struggling with high levels of organic waste in its wastewater. By engaging an experienced wastewater treatment supplier, the company adopted an advanced anaerobic digestion system. This solution effectively reduced organic load and produced biogas, which the company subsequently utilized as an energy source. The collaborative approach resulted in a significant decrease in energy costs and improved waste management practices, ultimately positioning the business as a leader in sustainability in its sector.

Furthermore, a chemical manufacturing firm demonstrated the advantages of strategic partnerships when it sought to upgrade its outdated wastewater treatment facility. By opting for a supplier known for innovative technologies, the firm benefited from a customized treatment solution that enhanced efficiency and reduced chemical usage by 25%. This transformation not only ensured compliance with stringent discharge regulations but also facilitated a more sustainable operational model. Such examples underscore the critical importance of selecting the right industrial wastewater treatment supplier to achieve long-term economic and environmental benefits.

Future Trends in Wastewater Treatment

The wastewater treatment industry is currently at a pivotal point, characterized by rapid advancements and evolving regulatory frameworks that emphasize sustainability and efficiency. As environmental concerns gain prominence across the globe, the demand for innovative solutions in industrial wastewater treatment continues to rise. Suppliers that stay ahead of these emerging trends can provide their clients with significant competitive advantages.

One notable innovation is the integration of advanced technologies such as membrane bioreactors (MBRs) and advanced oxidation processes (AOPs). These technologies not only improve the efficiency of treating wastewater but also enhance the quality of the effluent discharge. MBRs, for instance, combine conventional biological treatment with membrane filtration, offering superior contaminant removal and considerably smaller footprints than traditional systems. As such, partnering with a supplier who is well-versed in these technologies can ensure that businesses effectively meet stringent regulatory requirements while minimizing operational costs.

Additionally, there is a marked shift towards automation and smart monitoring solutions. Sensors and IoT (Internet of Things)-based systems are being deployed to optimize treatment processes in real-time. These innovations enable wastewater treatment facilities to manage resources more efficiently, reduce energy consumption, and ensure compliance with environmental regulations. A forward-thinking supplier who embraces these technologies can facilitate seamless upgrades, providing clients with peace of mind about maintaining their operations in line with current and future standards.

On the regulatory front, increasing government attention on water quality is prompting changes in wastewater treatment guidelines. Suppliers positioned to adapt swiftly to these evolving regulations not only help clients stay compliant but also introduce sustainable practices that can enhance corporate responsibility initiatives. As the industry continues to evolve, selecting the right wastewater treatment supplier will be crucial for businesses aiming to stay competitive and responsible in their water management efforts.

Conclusion: Making the Right Industrial Wastewater Treatment Supplier Choice

Choosing the right industrial wastewater treatment supplier is a critical decision that significantly impacts not only your company’s operational efficiency but also its sustainability efforts and regulatory compliance. Throughout this discussion, we have explored various aspects, including identifying a supplier’s credentials, understanding their technology and methods, and evaluating their service capabilities. These elements play a vital role in ensuring that your wastewater treatment needs are met effectively and responsibly.

When assessing potential suppliers, it is essential to prioritize those who demonstrate a solid understanding of your specific industry requirements and who can tailor solutions to meet your unique challenges. An ideal partner should not only provide reliable equipment and services but should also be willing to engage in long-term collaboration focused on reducing environmental impact and enhancing process efficiency. The evolving landscape of regulatory demands necessitates that companies remain proactive in their wastewater management strategies. Therefore, selecting a supplier that emphasizes compliance and sustainability could lead to better outcomes for your business while meeting local and national environmental protection standards.

Furthermore, fostering a partnership with a reputable industrial wastewater treatment supplier can lead to continuous improvement through innovation. Suppliers who invest in advancing their technologies and methodologies may offer you enhanced solutions that contribute to operational savings and transparency in your waste management processes.

Therefore, as you consider your options, reflect on the points raised throughout this blog post. It is crucial to conduct a thorough supplier evaluation process to ensure alignment with your company’s goals and values. Initiating this evaluation will position your business for success and safeguard against the challenges associated with inadequate wastewater management. Start today to partner with a supplier that can elevate your wastewater treatment approach to new heights.