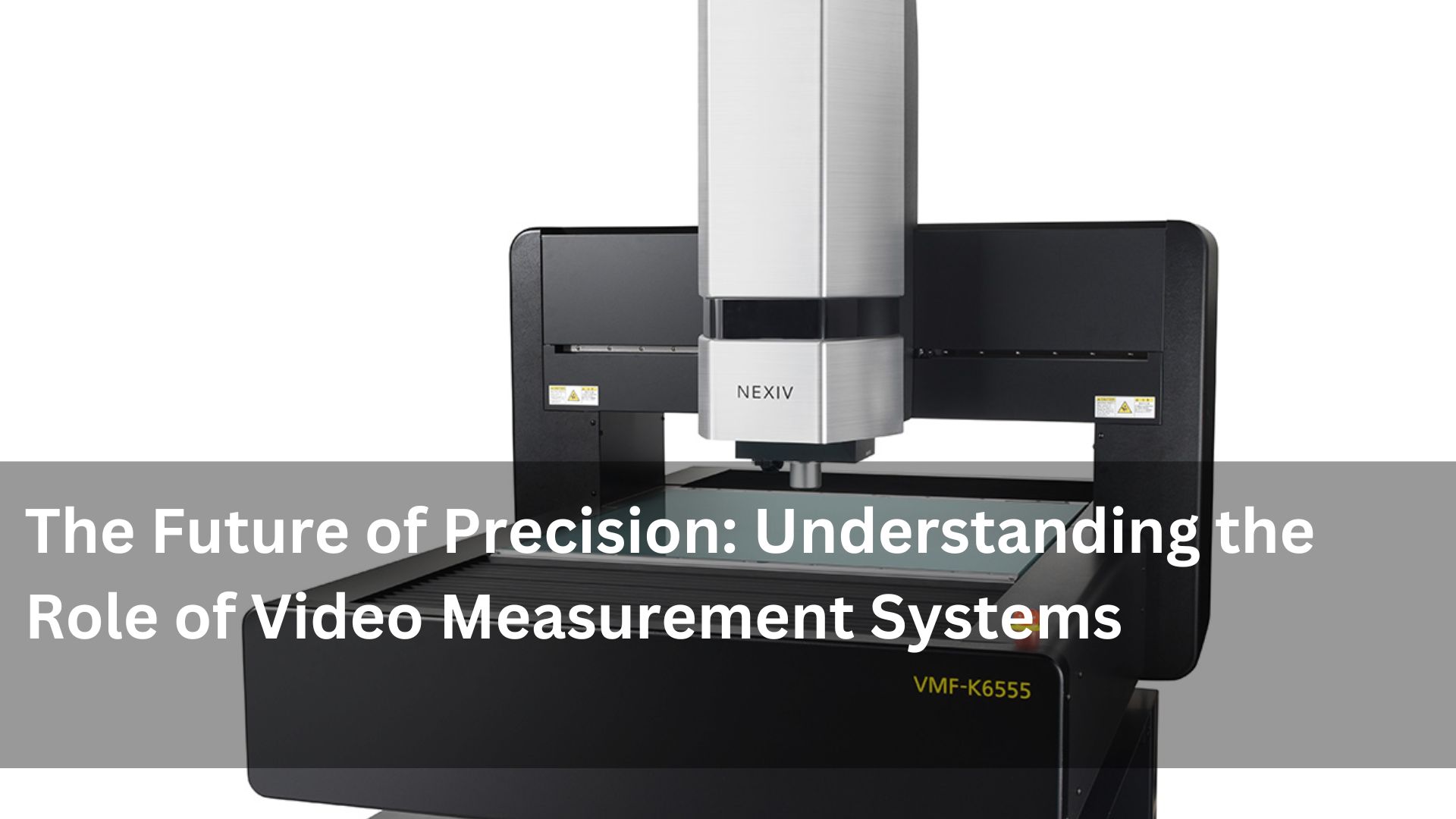

In today’s fast-paced industrial environment, accuracy and speed are paramount. Whether in aerospace, electronics, automotive, or manufacturing, companies continuously strive to meet tight tolerances and high-quality standards. One revolutionary technology that is redefining the boundaries of precision is the video measurement system. With its ability to deliver high-speed, non-contact, and highly accurate measurements, video measurement systems are becoming indispensable tools in quality control and assurance processes. This article explores what video measurement systems are, how they work, their benefits, applications, and why they are shaping the future of metrology.

What is a Video Measurement System?

A video measurement system (VMS) is an optical measuring device that uses high-resolution cameras, lenses, and lighting to capture and analyze the dimensions and geometries of objects. Unlike traditional contact-based measurement tools, a VMS operates without physical contact, making it ideal for delicate or intricate parts. These systems often include features such as zoom optics, 2D or 3D measurement capabilities, digital image processing, and software integration for data analysis and reporting.

How Video Measurement Systems Work

The core principle of a video measurement system involves capturing an image of the object through a camera and analyzing it using sophisticated software. Here’s a simplified process:

Illumination: Light sources, often LED or ring lights, illuminate the object to ensure clarity.

Image Capture: High-resolution cameras take real-time images of the object.

Magnification: Lenses magnify the image for more detailed inspection.

Software Analysis: Specialized software measures edges, angles, diameters, and other geometrical features.

Data Output: Results are recorded and can be integrated into larger QA systems.

This non-contact approach allows for precise, repeatable measurements, particularly beneficial for micro-components.

Key Benefits of Using a Video Measurement System

Implementing a video measurement system brings numerous advantages:

High Precision: Capable of measuring components with micron-level accuracy.

Speed: Rapid inspection reduces cycle times in production.

Non-Contact: Avoids part damage or deformation.

Repeatability: Delivers consistent results across multiple measurements.

Versatility: Supports a wide range of materials and part sizes.

Automation: Many systems can be programmed for automated inspection routines.

Applications of Video Measurement Systems Across Industries

Video measurement systems are highly adaptable and find use across multiple industries:

Electronics: Measuring microchips, PCBs, and miniature components.

Automotive: Ensuring dimensional accuracy of engine parts and injection molds.

Aerospace: Inspecting precision parts such as turbine blades and composite materials.

Medical Devices: Measuring surgical instruments and implants.

Plastics and Moldings: Verifying part conformance to CAD specifications.

Each industry benefits from the system’s ability to inspect complex geometries that are otherwise difficult to assess.

Types of Video Measurement Systems

There are several configurations of video measurement systems available, depending on the complexity of the task:

Manual VMS: Operated manually by technicians, suitable for simple parts.

Semi-Automated VMS: Offers programmable movements and software-driven inspections.

Fully Automated VMS: Integrated with robotic arms or CNC systems for complete automation.

2D vs. 3D VMS: 3D systems provide depth analysis and are ideal for more complex geometries.

Choosing the right system depends on your inspection needs, part complexity, and throughput requirements.

Key Features to Look for in a Video Measurement System

When selecting a video measurement system, consider these essential features:

Camera Resolution: Higher resolution ensures more accurate measurements.

Magnification Range: Zoom capabilities affect how detailed the inspection can be.

Measurement Software: User-friendly, with features like auto edge detection, CAD comparison, and reporting tools.

XY Table Size: Determines the maximum part size that can be inspected.

Lighting Options: Adjustable lighting enhances image clarity.

Connectivity: Ability to connect with QA software or MES systems.

Challenges and Limitations of Video Measurement Systems

Despite their advantages, video measurement systems are not without limitations:

Initial Cost: High upfront investment, especially for advanced systems.

Training Requirements: Operators need to be trained to handle software and hardware.

Environmental Sensitivity: Systems may require a controlled environment to maintain accuracy.

Surface Limitations: Highly reflective or transparent surfaces can affect measurement accuracy.

Understanding these limitations helps in planning integration and ensuring optimal system performance.

The Future of Video Measurement Systems

The evolution of video measurement systems is closely tied to advancements in imaging, AI, and data analytics. Future trends include:

AI-Driven Inspections: Machine learning to identify defects and classify components.

Cloud Integration: Remote monitoring and data sharing across production sites.

IoT and Industry 4.0: Integration into smart factory ecosystems for real-time feedback.

Augmented Reality: Visualizing measurement overlays in real-world environments.

As these innovations mature, video measurement systems will become even more integral to quality assurance and precision manufacturing.

Conclusion

The video measurement system is more than just a tool; it’s a strategic asset for quality-driven industries. Its precision, speed, and versatility offer a competitive edge, helping manufacturers meet strict standards while maintaining efficiency. As technology continues to evolve, investing in a video measurement system is not just beneficial—it’s essential for staying ahead in today’s industrial landscape. Whether you’re in electronics, automotive, aerospace, or medical device manufacturing, embracing this technology could be the key to unlocking greater accuracy and productivity.