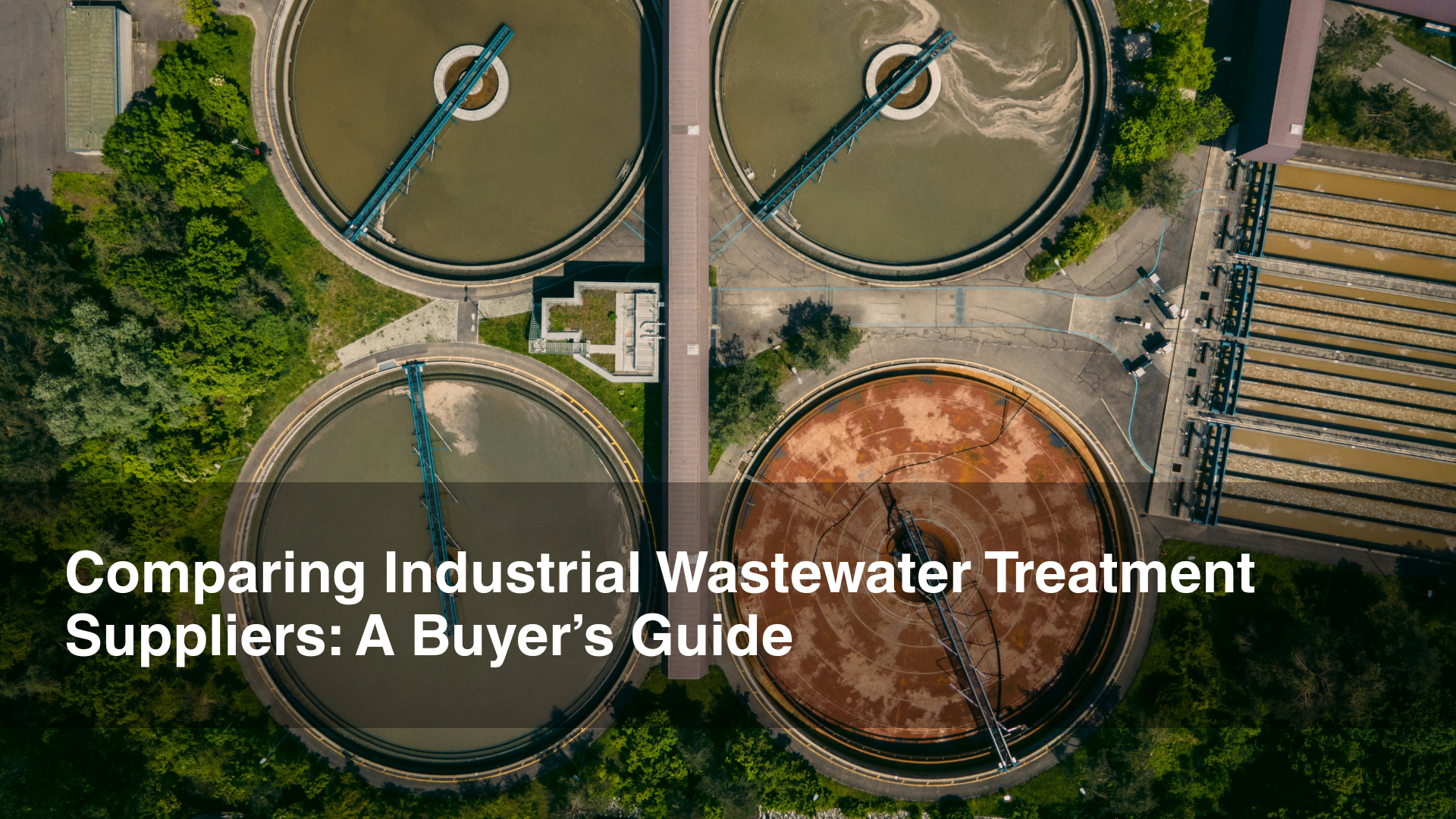

Introduction to Industrial Wastewater Treatment

In the contemporary landscape of manufacturing and production, the significance of effective industrial wastewater treatment cannot be overstated. As industries continue to expand, the volume of wastewater generated has increased proportionately. This trend necessitates not only efficient treatment methods but also strict compliance with growing regulatory mandates aimed at protecting environmental integrity and public health. The regulations surrounding wastewater management are becoming progressively stringent, compelling industries to adopt more sustainable practices for managing effluents. Failure to comply can lead to substantial legal repercussions, financial penalties, and damage to a company’s reputation.

The treatment of industrial wastewater involves a multifaceted approach that seeks to reduce pollutants to acceptable levels, thereby facilitating safe discharge or reuse. The involvement of a reliable industrial wastewater treatment supplier is crucial in this process. These suppliers offer advanced technologies and solutions tailored to meet the unique requirements of various industries. Their expertise enables businesses to navigate technical challenges while optimizing treatment processes, thus contributing to overall environmental sustainability. Furthermore, with the rise of global awareness regarding environmental issues, industries are increasingly recognizing that implementing effective wastewater treatment solutions is not merely a regulatory obligation but a corporate imperative.

Key Challenges in Industrial Wastewater Management

Industries across various sectors are increasingly confronted with a myriad of challenges in managing industrial wastewater. One of the foremost issues is the contamination of wastewater, which can arise from toxic chemicals, heavy metals, and persistent organic pollutants. These contaminants not only pose significant risks to public health but also adversely affect aquatic ecosystems when they are discharged without proper treatment. The responsibility of an industrial wastewater treatment supplier becomes evident here, as effective treatment solutions are essential to mitigate these risks.

Moreover, regulatory compliance presents another daunting challenge for industries. Governments and environmental agencies impose stringent regulations to ensure that wastewater treatment practices align with established environmental standards. Failing to comply with these regulations can lead to hefty fines, legal repercussions, and damage to a company’s reputation. Thus, industries must invest in reliable wastewater management systems that can efficiently treat contaminants and ensure adherence to regulations.

The financial implications of wastewater treatment also cannot be overlooked. Treatment costs can be substantial, particularly for industries dealing with complex wastewater streams. Maintaining and upgrading treatment facilities to meet evolving standards entails significant capital investment. As a result, many companies are exploring cost-effective wastewater management solutions that not only address regulatory requirements but also contribute to operational efficiency.

Additionally, there is an increasing imperative for industries to develop efficient waste reduction methods. This is driven by both environmental concerns and the need for sustainable practices. Industries are seeking innovative wastewater treatment technologies that not only alleviate their waste management challenges but also support their corporate social responsibility initiatives. In light of these multifaceted challenges, the collaboration with an adept industrial wastewater treatment supplier can be pivotal in devising comprehensive solutions tailored to specific industry needs.

Advancements in Membrane Technology by Industrial Wastewater Treatment Suppliers

Membrane technologies have emerged as groundbreaking solutions in the field of industrial wastewater treatment. By employing techniques such as ultrafiltration, nanofiltration, and reverse osmosis, industrial facilities can achieve significant improvements in water quality, thereby addressing the pressing challenges associated with wastewater management. Each of these membrane processes operates on distinct principles, offering various benefits and applications.

Ultrafiltration utilizes a semi-permeable membrane to separate particles based on size. This technology effectively removes suspended solids, colloids, and macromolecules from wastewater, making it an invaluable tool for industries requiring high-quality effluent. Similarly, nanofiltration serves a dual purpose by rejecting divalent ions while allowing monovalent ions to pass through. This selective permeability makes it especially beneficial for applications relating to food processing and chemical manufacturing, where specific removal of contaminants is necessary.

On the other hand, reverse osmosis operates by applying pressure to overcome osmotic forces, forcing water through a membrane that retains a majority of dissolved salts and contaminants. As a result, reverse osmosis is capable of producing water that meets even the most stringent quality standards. This advanced membrane technology has seen increasing adoption among industrial wastewater treatment suppliers, particularly in sectors such as pharmaceuticals, textiles, and electronics, where the quality of water is critical.

Furthermore, the integration of these membrane technologies into comprehensive treatment systems has been shown to enhance overall efficiency and reliability. By employing a multi-barrier approach, industries can not only mitigate environmental impacts but also comply with regulatory requirements and contribute to sustainable practices. As the demand for cleaner water continues to rise, the adoption of membrane technologies is expected to accelerate, further solidifying their role as essential components in the face of modern wastewater challenges.

Biotechnology Applications Offered by Industrial Wastewater Treatment Suppliers

The integration of biotechnology in industrial wastewater treatment has emerged as a promising avenue for addressing the complexities associated with effluent management in various sectors. Innovations such as bioaugmentation, bioreactors, and microbial fuel cells exemplify the effectiveness of biological treatment methods, positioning them as viable alternatives to traditional chemical and physical processes. These advanced techniques leverage the natural capabilities of microorganisms to degrade pollutants, resulting in less chemical usage and a more eco-friendly approach.

Bioaugmentation involves the intentional introduction of beneficial microorganisms into the wastewater treatment system to enhance its treatment efficiency. This process can significantly improve the breakdown of organic matter and toxic substances that conventional methods may struggle to remove. Additionally, bioreactors that are designed to optimize the growth and activity of these microorganisms provide a controlled environment for enhanced degradation processes. These biotechnological innovations have demonstrated substantial reductions in biochemical oxygen demand (BOD) and total suspended solids (TSS), leading to cleaner effluent being released into the environment.

Another notable application is the use of microbial fuel cells (MFCs), which not only treat wastewater but also generate electricity as a byproduct. This dual function illustrates how biotechnology can pave the way towards sustainable energy solutions, presenting a unique value proposition for industries keen on reducing their carbon footprint while managing wastewater effectively. Case studies have shown that MFCs can successfully operate in various industrial settings, yielding promising results in terms of both energy recovery and waste remediation.

In contrast to conventional methods, which often require extensive energy and chemical inputs, biological treatment systems foster a more sustainable approach to wastewater management. As industries continue to seek more efficient and environmentally responsible solutions, the role of an industrial wastewater treatment supplier in providing biotechnological innovations cannot be overstated. These advancements are critical in meeting regulatory compliance while promoting ecological sustainability.

Advanced Oxidation Processes (AOPs) from Leading Industrial Wastewater Treatment Suppliers

Advanced Oxidation Processes (AOPs) represent a class of innovative technologies designed to significantly enhance the treatment of industrial wastewater. By utilizing powerful oxidizing agents, these processes effectively decompose a wide array of organic pollutants that are often resistant to conventional treatment methods. Among the various AOPs, ozone treatment, Fenton’s reaction, and ultraviolet (UV) oxidation are prominent examples that have gained traction in recent years due to their efficiency and versatility.

Ozone treatment, characterized by its high oxidizing potential, is particularly effective in breaking down complex organic compounds in wastewater. Ozone is generated on-site and can rapidly react with contaminants, making this process not only efficient but also environmentally friendly. The main challenge, however, lies in its operational costs and the requirement for careful management to ensure the effective transfer of ozone into the wastewater stream, further emphasizing the need for a knowledgeable industrial wastewater treatment supplier.

Fenton’s reaction, on the other hand, utilizes a combination of hydrogen peroxide and ferrous iron to produce hydroxyl radicals that effectively oxidize organic matter. This process is particularly advantageous for treating effluents with high concentrations of contaminants. Nonetheless, Fenton’s reaction requires precise control of pH levels and reagent concentration to optimize performance, which necessitates expertise in operational management. An industrial wastewater treatment supplier can play a crucial role in implementing this technology safely and effectively.

UV oxidation represents another AOP that employs ultraviolet light to activate oxidants, such as hydrogen peroxide, leading to the generation of hydroxyl radicals. This method is recognized for its ability to target specific pollutants, offering tailored solutions for various industries. Although UV treatment may have higher initial setup costs, its low operational costs and minimal chemical requirement over time can provide long-term cost savings.

In conclusion, Advanced Oxidation Processes offer cutting-edge solutions to address the intricate challenges of industrial wastewater treatment. Their varied applications showcase the potential of these technologies to enhance degradation efficiency, while also highlighting the importance of selecting a proficient industrial wastewater treatment supplier to navigate the complexities of implementation and operation.

Smart Technologies and Automation Used by Industrial Wastewater Treatment Suppliers

In recent years, the integration of smart technologies and automation has fundamentally transformed the landscape of industrial wastewater treatment. The rise of the Internet of Things (IoT) has enabled facilities to monitor water quality and treatment processes in real time, leading to optimized operations. By connecting treatment equipment and sensors through the IoT, operators can gather critical data that informs more efficient management practices.

Real-time data analytics plays a pivotal role in assessing water quality parameters, such as pH, turbidity, and biochemical oxygen demand. These analytics allow industrial wastewater treatment suppliers to identify potential issues before they escalate into more significant problems. For instance, when sensors detect deviations from expected water quality metrics, automated systems can initiate corrective actions, such as adjusting chemical dosing or changing filtration rates. This real-time response not only enhances the effectiveness of treatment methods but also minimizes chemical usage and reduces operational costs.

Furthermore, machine learning techniques are being employed to predict operational anomalies and optimize treatment processes based on historical data. By training algorithms on past performance metrics, facilities can develop predictive maintenance schedules that prevent equipment failures. This proactive approach not only extends the life of treatment equipment but also ensures uninterrupted service, contributing to overall productivity. As these smart technologies and automation systems become increasingly prevalent in wastewater treatment, they provide a competitive edge for industrial wastewater treatment suppliers. Thus, the adoption of such innovations fosters the development of sustainable practices and compliance with regulatory standards.

As the industry evolves, the collaboration between technology providers and wastewater treatment facilities will be crucial in addressing modern challenges. The ongoing implementation of these technologies is set to usher in a new era of efficiency and accountability in industrial wastewater management.

Decentralized Treatment Systems: A Sustainable Approach

Decentralized wastewater treatment systems have emerged as a sustainable alternative to traditional centralized methods, particularly in industrial contexts. These systems treat wastewater on-site, resulting in various advantages, such as reduced transportation costs, improved response times, and enhanced adaptability across different industrial settings. As industries face stricter regulations and increasing pressure to minimize environmental impact, the importance of innovative treatment technologies continues to grow.

One significant advantage of decentralized treatment is the reduction in the need for wastewater transportation. Centralized systems often require extensive piping networks to transport wastewater from industrial facilities to treatment plants, incurring high costs and lengthy delays. Decentralized solutions eliminate this need by treating wastewater where it is generated, thus streamlining the process and decreasing associated costs. This not only saves resources but also minimizes the carbon footprint linked to wastewater transport, aligning with sustainability goals.

Moreover, decentralized systems can be tailored to specific industrial requirements, making them highly adaptable. Different industries produce varying types and quantities of wastewater, and a one-size-fits-all approach may not suffice. However, with a variety of technologies available—like membrane bioreactors, constructed wetlands, and aerobic treatment units—industrial users can select a system that best fits their needs. This adaptability also allows for faster installation and modified treatment processes in response to changing regulations or operational demands.

Successful case studies lend credence to the effectiveness of decentralized systems. For example, a manufacturing facility implemented a decentralized treatment solution, leading to a significant reduction in operational costs and treatment times. By collaborating with an industrial wastewater treatment supplier, the facility was able to develop a system that not only met regulatory standards but also provided a model for sustainable practices within the industry.

In conclusion, decentralized wastewater treatment systems represent a vital step toward achieving sustainable industrial practices. By alleviating transportation challenges, enhancing adaptability, and demonstrating effective outcomes, these systems pave the way for a cleaner and more efficient approach to managing industrial wastewater.

Regulatory Trends and Compliance in Wastewater Treatment

The regulatory landscape surrounding industrial wastewater treatment is continuously evolving, driven by increasing environmental concerns and the need for sustainable practices. Governments and regulatory bodies worldwide are instituting stricter regulations to mitigate the impact of industrial effluents on ecosystems and public health. These regulations often stipulate specific limits on the types of pollutants that can be discharged, pushing industries to adopt more advanced technologies. For manufacturers and suppliers, staying compliant is not just about avoiding penalties; it also offers an opportunity for innovation.

Currently, regulations such as the Clean Water Act in the United States and the European Union’s Water Framework Directive are fundamental in shaping industrial practices. These regulations mandate rigorous monitoring and reporting of wastewater quality, compelling industries to engage with reliable industrial wastewater treatment suppliers who can provide state-of-the-art solutions that meet compliance requirements. Technologies such as membrane filtration, advanced oxidation processes, and biological treatment methods have emerged as vital tools in achieving compliance. Suppliers are increasingly incorporating these technologies into their offerings, ensuring that industries can effectively treat their wastewater while adhering to regulatory standards.

Looking toward the future, trends indicate a potential shift towards stricter regulations that further emphasize the reduction of hazardous pollutants and the recycling of treated wastewater. This evolving compliance landscape will drive innovation among industrial wastewater treatment suppliers, pushing them to develop systems that not only meet current regulations but anticipate future requirements. Companies are investing in research and development to create adaptable and efficient treatment solutions that help industries transition toward sustainable practices. As regulations tighten, the collaboration between industries and wastewater treatment suppliers will become crucial, not only for compliance but also for the advancement of environmentally responsible manufacturing processes.

Conclusion and Future Outlook for Industrial Wastewater Treatment Suppliers

The field of industrial wastewater treatment has witnessed significant advancements in recent years, driven by the introduction of innovative technologies. These advancements have not only enhanced the efficiency and effectiveness of treatment processes but have also created opportunities for industries to adopt more sustainable practices. The role of the industrial wastewater treatment supplier has become increasingly crucial as they deliver state-of-the-art solutions that address both environmental and regulatory requirements.

Emerging technologies, such as membrane bioreactors, advanced oxidation processes, and real-time monitoring systems, have shown promising results in reducing pollutants and reclaiming water. These solutions have enabled industries to minimize their ecological footprint while ensuring compliance with stringent regulations. Furthermore, the integration of artificial intelligence and machine learning in treatment systems allows for optimized operations, leading to enhanced performance and cost savings. This transformational change showcases the potential for ongoing improvements in industrial wastewater treatment.

Looking ahead, the collaboration between industrial sectors, wastewater treatment suppliers, and regulatory agencies will be pivotal in driving future innovations. By fostering partnerships, stakeholders can share knowledge, resources, and best practices, ultimately paving the way for more sustainable and resilient wastewater management solutions. As industries evolve, their needs will also change, presenting challenges that require innovative thinking and adaptability in treatment strategies.

In conclusion, the future of industrial wastewater treatment is bright, as advancements in technology continue to emerge. By leveraging the expertise of industrial wastewater treatment suppliers and focusing on collaborative efforts, the industry can develop new solutions that not only address current challenges but also anticipate future demands. The journey towards sustainable wastewater management is ongoing, and the association among industries, suppliers, and regulatory bodies will play a critical role in shaping the future landscape of this vital field.